Feature Dimensions

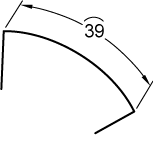

- An arc length is dimensioned using the arc length symbol.

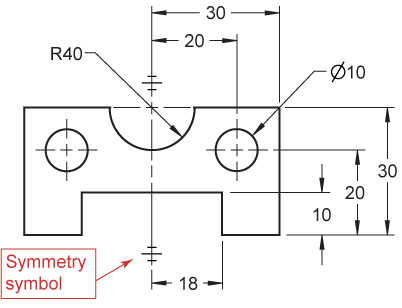

- For a symmetric part, it is only necessary to dimension to one side of the center line of symmetry.

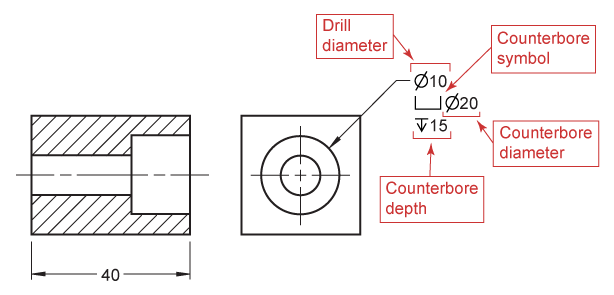

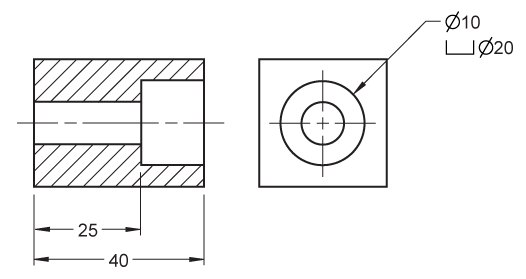

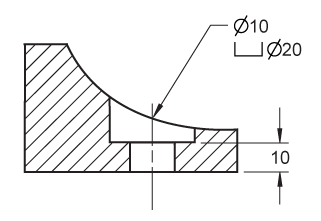

- Counterbored holes are specified by giving the diameter of the drill, the diameter of the counterbore, and the depth of the counterbore. If the thickness of the material below the counterbore is significant, this thickness rather than the counterbore depth is given.

What do you think a counterbored hole is used for?

- Spotfaced Holes: The difference between a C’BORE and a Spotface is that the machining operation occurs on a curved surface.

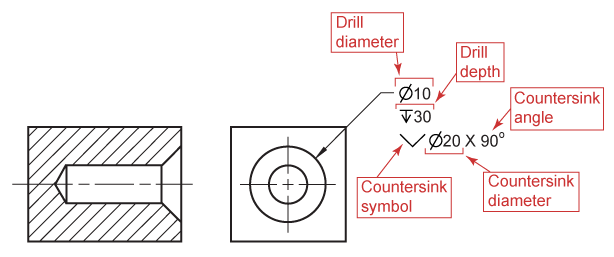

- Countersunk holes are specified by giving the diameter of the drill, the diameter of the countersink, and the angle of the countersink.

What do you think a countersunk hole is used for?

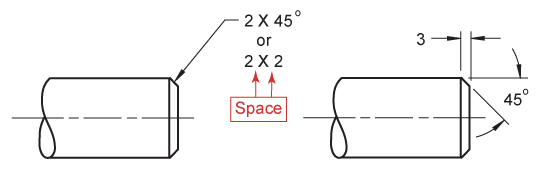

- Chamfers are dimensioned by a linear dimension and an angle, or by two linear dimensions.

What do you think a chamfer is used for?

Drawing Notes

Drawing notes give additional information that is used to complement conventional dimensions.

- manufacturing requirements

- treatments

- finishes

- blanket dimensions

The note area is identified with the heading “NOTE:”. Here are some examples.

NOTE: ALL FILLETS AND ROUNDS 3 MM UNLESS OTHERWISE SPECIFIED.

NOTE: REMOVE BURRS AND BREAK SHARP EDGES.

NOTE: APPLICABLE STANDARDS: ASME Y14.5-2009, ASME Y14.41-2003